- +91-821-983-3540

- 01762-503026

- info@pharmaffairs.in

Facility Upgradation and Expansion

Home » Facility Upgradation and Expansion

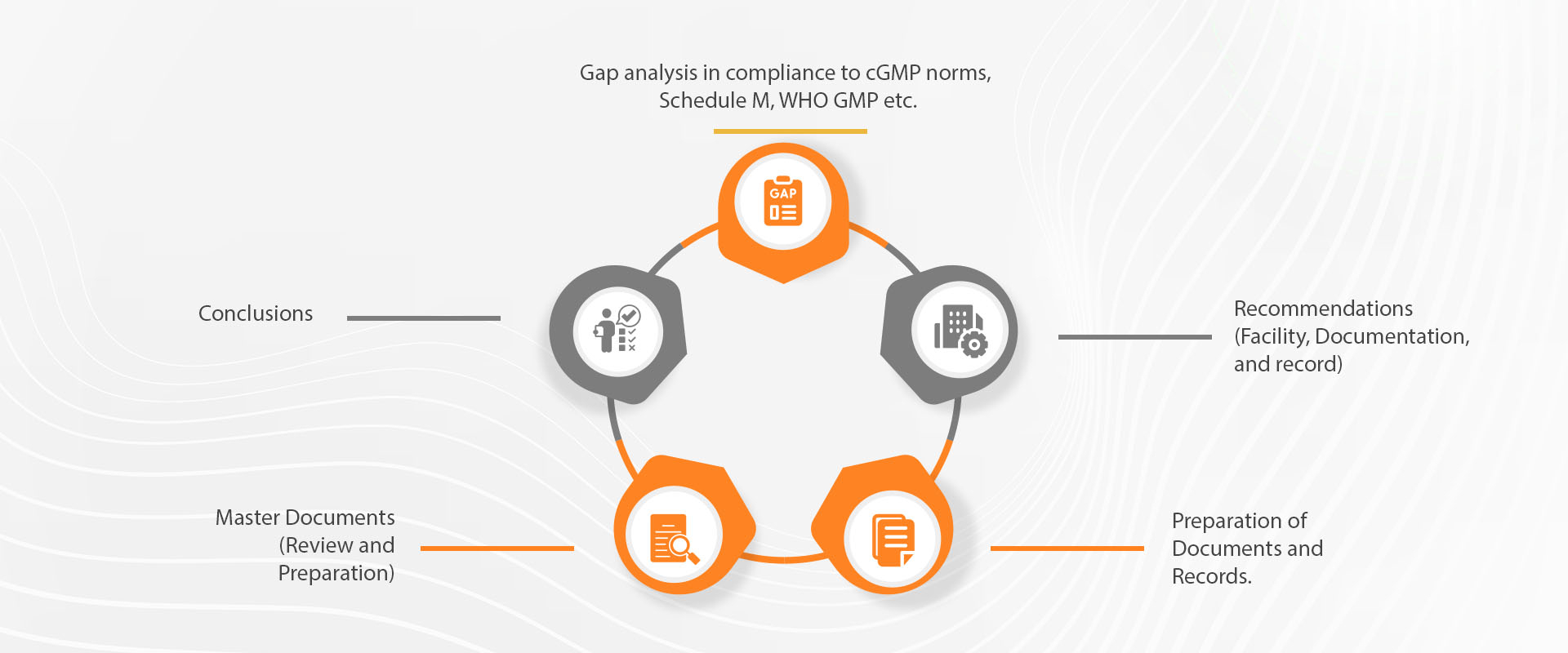

Gap analysis in compliance to cGMP norms, Schedule M, WHO GMP etc.

Recommendations (Facility, Documentation, and record)

Preparation of Documents and Records.

Master Documents (Review and Preparation)

Conclusions

STEP-1

Gap analysis in cGMP norms, Schedule M, WHO GMP etc. compliance level.

a. Comprehensive review of the facility about the movement of personnel and materials, the input of materials, area movement spatial requirements, etc.

b. Department Documentation and Records: Quality Assurance, Production, Quality Control Laboratory, Store, Utilities, and Human Resource Management etc.

STEP-2

Recommendations (Facility, Documentation, and record)

a. Revised Plans-Production area, Warehouse Utilities, QC etc.

b. Documentation pertaining to QC, QA, Production, Warehouse, Utilities, and HR offered and supervised.

c. Other necessary equipment and machines.

STEP-3

Document and Record Preparation

a. Update and review current documentation.

b. Develop supplemental documentation and conduct training.

c. SOPs

- Prepare, Maintain and record keeping documentation Philosophy.

- Assisting QA/QC Sample SOP preparations (HPLC, UV, Dissolution Rate Apparatus; Production – FBD; Compression machine; Primary Packing lines; Warehouse – Sampling and Dispensing; Utilities – Air compressor, HVAC), Human Resources.

- Stability Studies.

- Assistance in Product Recall & Complaint Management

STEP-4

Master Document (Review and Preparation)

- Master Validation Plan: Area, equipment, process, cleaning etc.

- Existing documents review and prepare/update them. Assist in the preparation of sample documents MFR: Master Formula Record, BMR: Batch Manufacturing Record, MPR: Master Packing Record, BPR: Batch Packing Record.

STEP-5

Conclusions

- Self-Audit and assessment.

- Preparation for External Audit clearance

- Regulatory Compliance